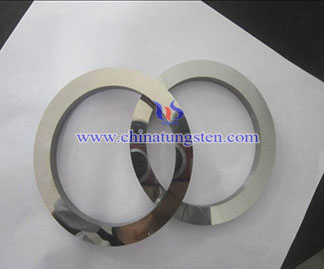

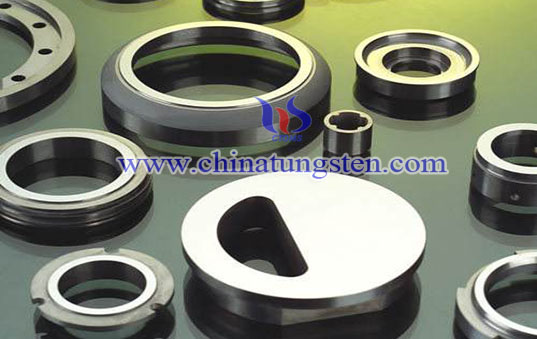

cemented carbide wear resistant tools

The most important characteristic of cemented carbide is its wear resistance; it is suitable for making wear-resistant tools. The development of wear resistant tools towards higher rates of stock removal is largely the result of adding a higher percentage of hard particles or carbides to the material. Thus hardened carbon steel with only a small percentage of carbides or high-speed steel, which contains some 20% of carbides, have considerably less wear resistance and heat stability than cemented carbide, which contains some 90% of carbides. The unique composition of cemented carbide provides stability and high productivity in production, DWI process, forming and stamping operations in the can manufacturing industry, which makes Cemented Carbide the ideal tool material.

Chinatungsten Online's cemented carbide wear-resistant tools are manufactured based on our advanced cemented carbide manufacturing technology and professional processing skills. Cemented carbide has excellent qualities such as high wear resistance, high elasticity, and high compressive strength capabilities. Our customers in many industries really appreciate to use them.

In addition, by utilizing our super-accurate manufacturing technology we supply cemented carbide wear-resistant tools to many fileds such as IT and environment-related industries. We are very confident that our cemented carbide wear-resistant tools, which have resulted from the mixture of our rich experience and know-how regarding cemented carbide materials as well as our excellent manufacturing technology, serve with our customers very well.